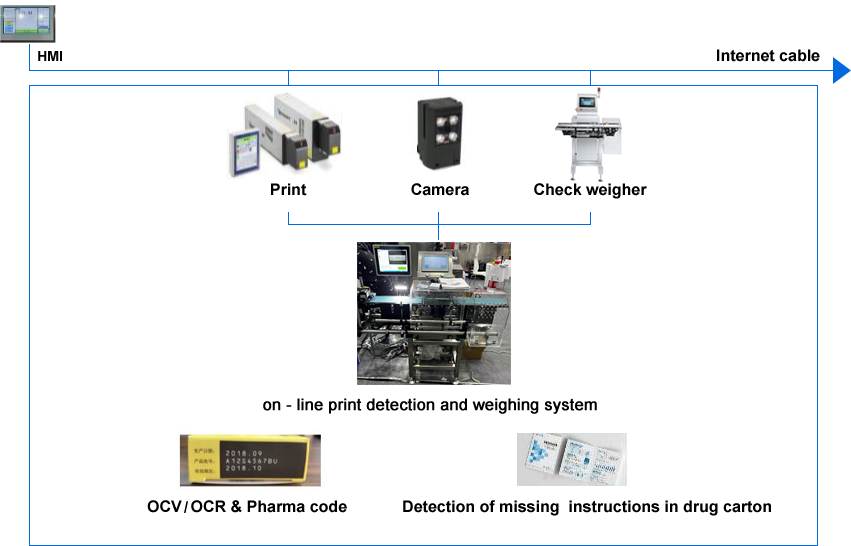

On-line print detection and weighing system

Weigh smarter, work faster

Basic needs

During the weighing process, due to various reasons, such as printing itself problems, or packaging line transmission problems, signal output problems, etc., will cause a variety of potential print quality defects. This defect will directly bring consumers reading obstacles and confusion, in order to avoid such problems, effectively improve the quality of packaging, it is recommended that before weighing, are matched with the corresponding printing and visual detection.

Combination of printer & camera and weighing system

We usually use the world-famous Canadian brand Dalsa vision system and the 30-year-old Chinese domestic brand printer as well as our self-developed weighing system Weightwell.

Dalsa’s new generation of intelligent cameras and online printing equipment, the perfect combination of online weighing system, to provide customers with tailor-made professional solutions.

Solution

When the template is set, after being used in the printer & camera and weighing system, the front print and visual inspection, and the back weigh inspection, thus effectively identifying potential quality problems in the printing process.

System advantage

Less space is used, and one rejection system can be used, which is more cost-effective than buying a combination separately and avoids signal transmission problems for a more stable, all-in-one solution

HMI, human machine interface, can be flexibly selected. It can be installed on the customer’s computer system or can use Weightwell’s HMI

To meet basic needs, customers can choose whether to configure other brand printer and vision system combinations, enabling online control of printer & camera and weighing. With a single setup, the template can be sent to the printer & camera and the weighing system for efficient execution

The system also has flexible module expansion. In addition to providing basic online print & visual inspection and weighing inspection, other inspection modules can also be extended. For example, in the production process, in order to avoid the wrong packaging materials in the packaging process, such as instructions, cartons, bags, etc., any packaging materials, then as long as the corresponding detection system, by comparing the bar code on the outer packaging, it can easily determine the correctness of the packaging materials, thus greatly reducing the risk of using the wrong packaging materials

In general, the whole system has rich scalability in meeting basic needs, allowing customers’ packaging lines to easily deal with various possible potential packagingquality problems through a one-stop solution.

Weightwell’s professional experience makes the weighing process easier, more efficient and safer!